It seems logical that today’s students should become familiar with the construction and use of robots. After all, even though we can’t predict exactly what the world will be like in the future, we know that robots and humans will increasingly work side-by-side. Factories, farms, hospitals, airports, banks, and grocery stores — just about everywhere physical labor is involved, the workplace our children will enter will look vastly different than our own. This can be a good thing: robots can be built and programmed to perform tasks efficiently and safely, without fatiguing and under adverse conditions, allowing the rest of us to focus on other tasks. Consequently, it seems natural to begin preparing our young people for this future world. Even if robotics weren’t an inevitable economic force, I think there’s a strong argument that robotics provides an amazing foil to teach children about the softer sides of being a successful adult. At my school we often ask ourselves, “How can we plan activities in which the children develop the skills and concepts they need while at the same time fostering the development of the socio-emotional competencies needed to function as content, productive adults?” It may seem unlikely, but I think robotics can be one answer: By setting up the conditions for children to design, build, and program robots in small groups, robotics can provide that magic mix of hands-on work, social interaction, and brain work. These three elements go a long way toward developing confidence, competence, social skills, and a sense of agency.

I use KIBOs to give my students the opportunity to practice risk-taking, creativity, engineering, and computational thinking skills. The KIBO is designed so that users can see and work “under the hood.” Unlike many forms of technology we use in our daily lives, students can actually see the circuit board and the power supply inside it, take it completely apart, and rebuild it in multiple configurations. As they construct and program with the KIBO kits, they are placed in a situation where they must make plans and decisions, test and debug, bump up against frustration and figure out what to do next. They are developing confidence, resilience, and a sense of agency with every step of the process.

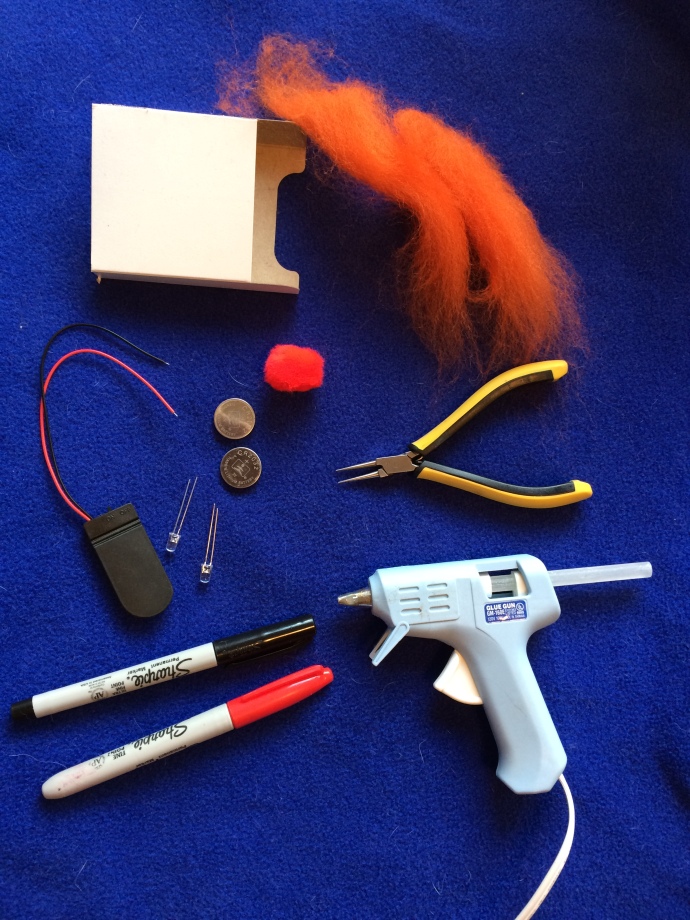

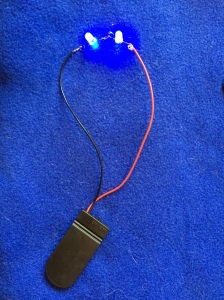

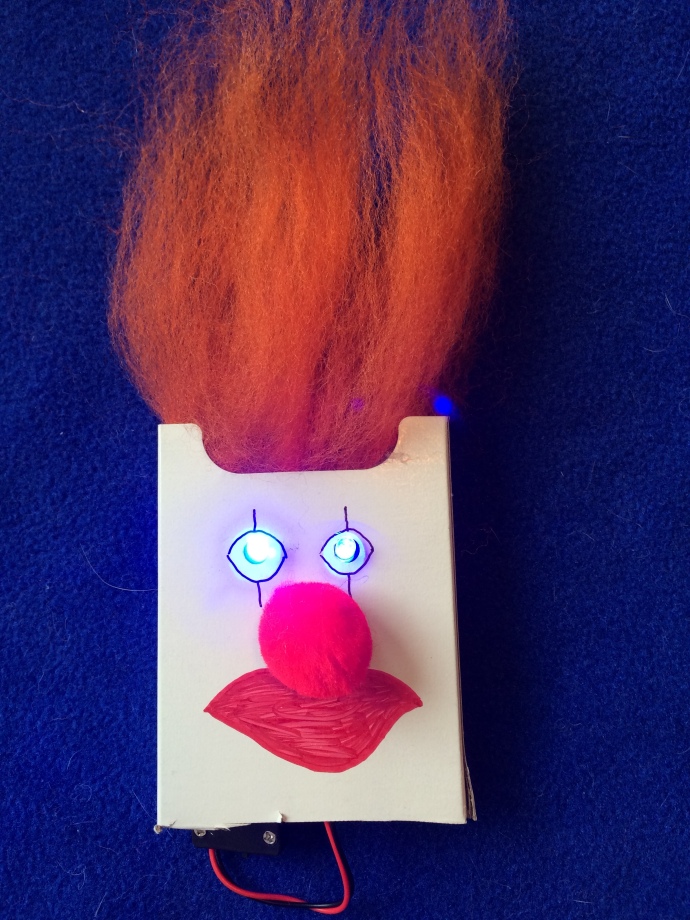

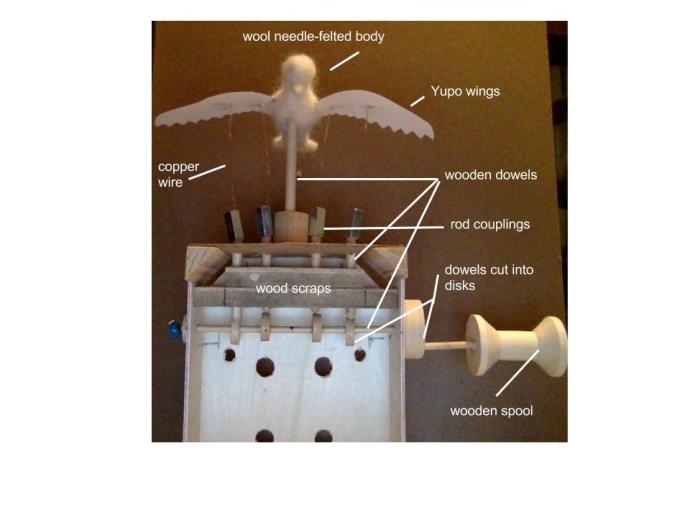

The KIBO’s input modules (the sound, light, and distance sensors) and output modules (sounds and recordings, lights, and motors) help students develop an understanding of how we program robots to interact with our world. There are several different kinds of platforms that can be added to the top of the KIBO, each allowing students to customize their robot with their own construction of craft materials or LEGOs. Adding a customized platform involves exercising some engineering skills to design, construct, and attach it. I’ve observed that using the platforms often increases the students’ investment in “making the robot work.” Suddenly, the KIBO goes from being an “it” to having a name and a persona.

The command blocks allow students to program movements, sounds, and lights using simple sequences of commands, repeat loops, and if-then statements. This promotes an understanding of some of the fundamental concepts used in computer programming. Programs are “written” with wooden blocks that are “read” by the KIBO through a scanner, eliminating the need for a tablet, laptop, or account of any kind. This means even the youngest learners can be both engineers and programmers. They start to develop an understanding of how robots are constructed, how their inputs, outputs, and appearance can be customized, and how they can be programmed to behave in a certain way or perform a task. This is very empowering.

Working and playing with KIBOs in small groups fosters valuable social skills such as explaining thoughts and feelings to others, listening carefully, sharing materials, and respecting and supporting each other’s ideas. Goodness knows, we need more of that in today’s world. Constructing a KIBO, building a customized top, and programming it to do what you want involves planning, risk-taking, problem-solving, iterating, and perhaps most importantly, persistence. In my classroom we talk openly about being frustrated and the strategies we can use to overcome it so we can keep moving forward. The kids always laugh when I ask them to show me their frustrated face. Then I ask them to show me their resilience muscle.

One of my favorite lessons is the introduction of the KIBO to our Junior Kindergarten. We read the book, Boy and Bot, by Ame Dyckman, and then we talk about the differences between real people and robots. I show them just the body of the KIBO and they are excited to see the circuit board and batteries inside. They notice the power switch and the ports where different modules can be attached. I don’t show them a built KIBO or tell them how to put it together. Instead, I give each group of children a box with a KIBO body, motors, wheels, and a light and I tell them that this is a box of parts to build a robot. As the children work together to figure out how to build it, there are lots of conversations about the possibilities, lots of negotiations, and lots of risk-taking going on. Inevitably, within fifteen minutes, we have a classroom full of working robots. They are all slightly different in construction and performance, but they are all moving across the floor in one way or another. This lesson is followed by a series of meetings during which the students iterate the construction of their robots and work with the coding blocks to program them to move, sing, light up, and respond to input. But I love this first lesson because it imparts to the children that we have confidence in their capacity as designers and engineers.

Children need to actually touch, manipulate, and experiment with objects in order to fully understand them. Robots bring this physical interaction to the potentially intimidating process of understanding engineering and programming. When paired with the social interaction of working with friends, we can deepen the understanding through conversation and idea sharing. The bonus is that, while the children are learning about engineering, robotics, and coding, they are practicing their ability to communicate and collaborate. I think they love that, for much of this process, they are in control. We have acknowledged our belief that they are capable engineers and programmers.

In our children’s future careers, the way they work, interact, and communicate will continue to evolve as it has during the lifetime of today’s adults. The products and services our children will design, build or sell will also evolve. New and exciting opportunities will exist for them. Many jobs will involve the design, construction, programming, and maintenance of automated tools, including robots. You don’t have to look too far to see prototypes already in development or in use: self-driven cars (Uber), home robotic companions and workers (Roomba, Pepper, Paro, and Jibo), and smart home hubs (Echo, Dot, and Google Home) to name just a few.

These new tools will be programmed with algorithms that enable them to “learn” and adapt to input (artificial intelligence). We already see this when we use services like Netflix and Goodreads: when we finish one video or book, they suggest what we might enjoy next based on our history and our ratings. I think it’s important that our children have at least a basic understanding of how these technologies work. They may have jobs designing these tools or deciding how they will look or how we will interface with them. More importantly, I would hope our students would have a well-polished moral compass to guide them in how these tools play a part in our lives and the choices we make when building and using them. This is why the social-emotional piece is so important. As we become more adept at building and programing machines to do our work, it becomes essential for someone to be making the ethical decisions about what these machines can do, how they will do it, and who will have access to them.

As with anything that we think is important, we start exposing children to the foundational skills and concepts when they are very young. The terms become part of their vocabulary, and if we are skillful in teaching the concepts in an age-appropriate way, the concepts become part of their general fund of knowledge. I use a lot of stories to explain the concepts of algorithms, repeats, events, functions, and conditionals to my students. They all come straight from real life so the children can relate to them. These concepts may sound foreign, but when you start to draw connections with real-life events, they become normalized and easier to understand. They are something the children can use when planning any task or event, from writing a book report to planning a playdate with a friend. I love it when a student asks me if I want to hear their algorithm for a task we don’t usually associate with computer programming.

Saying “Coding and robotics are for ‘big kids’” is like saying “Reading is for “big kids.” If we wait until a child is in middle school to hand them a book, we have not only devalued reading, we’ve also missed out on the opportunity to make it easy and fun. Beginning in Junior Kindergarten, all of our students work with robots and coding in some way. It’s not just for gifted students or older students – it’s for all students. By the time they finish fifth grade they have programmed several different kinds of robots to accomplish tasks such as navigating mazes, carrying cargo to specific destinations, and making decisions about when to move, light up, and make sounds and when to be still. Given the appropriate tools and the right introduction, you just need to step back and watch the magic happen.